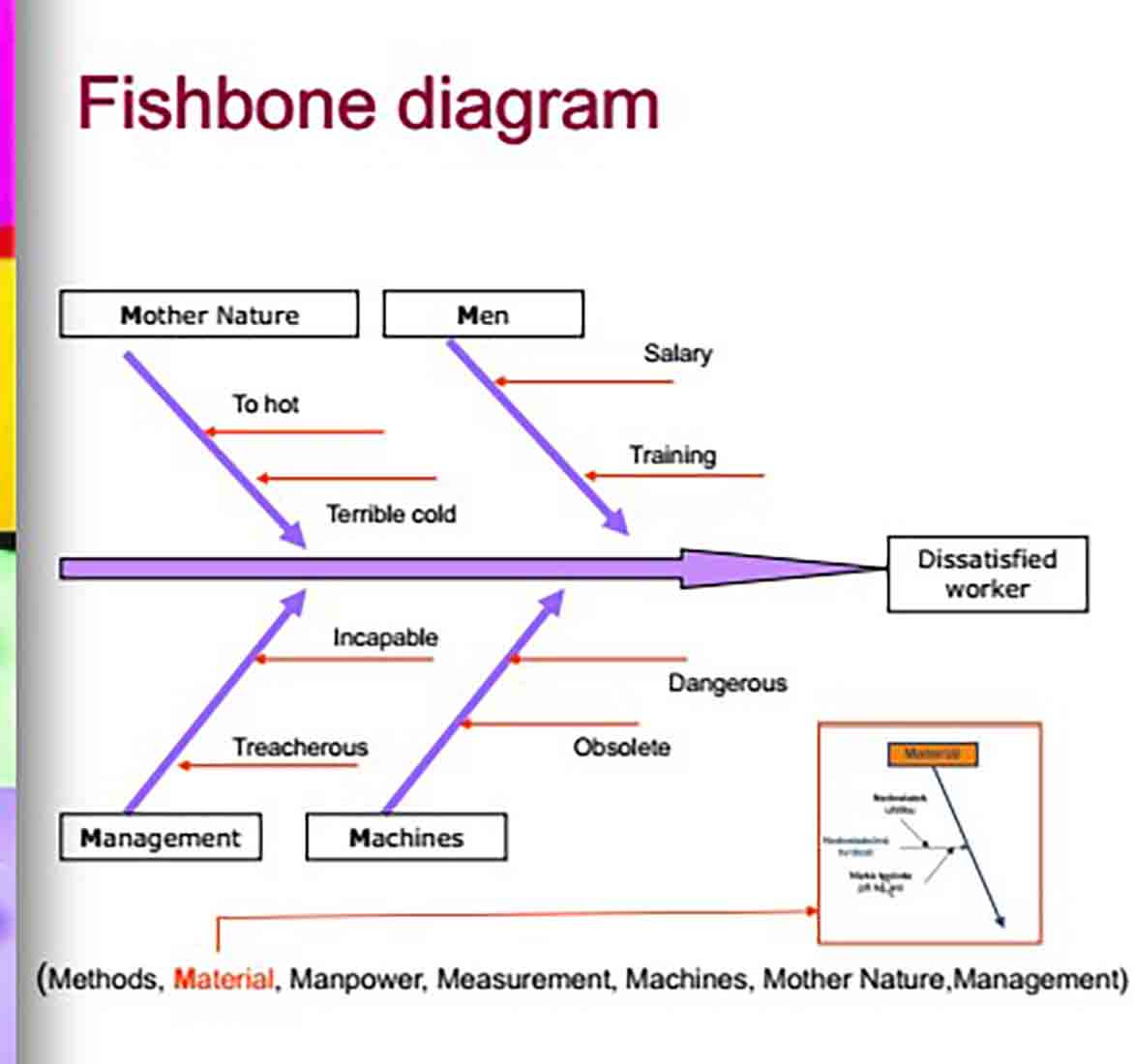

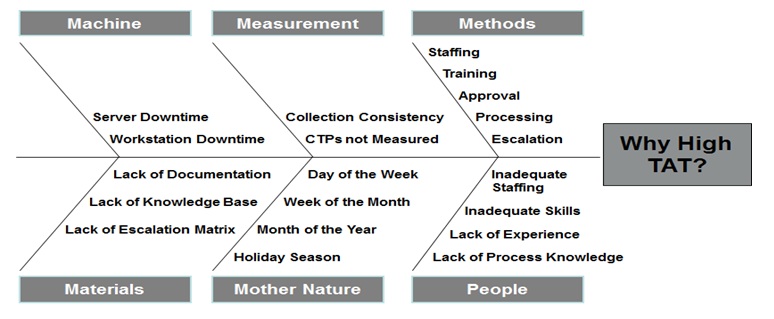

These categories are mostly used to draw a cause and effect diagram in the manufacturing industry. These are man, materials, machine, methods, measurements and mother nature. This Ishikawa diagram is based on the 6M’s of Six Sigma. These sections are procedures, policies, place/plant, products, people, procedures, price and promotion. This particular cause and effect diagram has eight sections, all of which start with a P – hence the name. This is another fishbone diagram that is popular in the service industry, although people in manufacturing and administrative function use it as well. You can use this fishbone diagram outside the service industry – as long as it applies. All potential causes, along with their information, are grouped into four sections: systems, surroundings, skills and suppliers. If your organization operates in the service industry, you will most likely use this fishbone diagram. So if you are using it in a restaurant setting, you can make sure that your diagram is different from one that can be made in a manufacturing plant. The affinities or sections are not predefined, allowing you to adapt it anyway you want to fit your organization and scenario. This is the basic and most commonly-used fishbone diagram. Here are a couple of fishbone diagrams that you can draw while you brainstorm.

Six Sigma Virtual Instructor-led Training.Please remember there is not a good approach to create plenty of sub-causes levels. For example insufficient temper can be caused with insufficient amount of carbon, low temperature during hardening process, etc. You can use this method for sub-causes specification, it means to analyze specified causes and look for causes of the causes. If it is detected you should look for new causes, relation among causes, etc. If the problem is not detected again you have found the root cause. Check the re-occurrence of the problem.use the Pareto analysis to prioritize the causes solution.Add data from the reporting system or dashboard (if they are available) to analyzed causes.Analyze the causes with the highest weight factors.

When all of your ideas and possibilities are exhausted, let’s every member of your team to evaluate the causes with weight factors.Define potential causes, a brainstorming can used, and add them to relevant bones, as well called as general areas.Add branches (bones) to the backbone and write down general areas, the causes can occur from:.Draw a horizontal line from the rectangle as a fish’s backbone. Draw a rectangle on the sheet and write into a problem to be solved.Prepare a team of colleagues who are somehow interested in the problem.It is useful to use more colors for each area or for the most probable causes. Prepare for yourself a big sheet of paper, the Ishikawa chart you will draw on it. There is an effect at the beginning, which has already happened or might happen as a potential and we would like to avoid its formation.

To be able to identify the problem’s solution, the causes are demonstrated into the chart.ĭuring the Ishikawa diagram creation the brainstorming method shall be used in order to help us to specify all, even low probable, causes of solved problem. If you are not able to start a car it can be a set of causes – flat battery, shortage of fuel, imperfect plugs, electrical circuit shortage, broken central control section, etc. It is based on the basic principle – each and every effect (a problem) has its cause or combination of causes. Not any consulting should not avoid use it for looking for the problem causes and nonconformities nowadays. Just this diagram is very often used in the quality discipline. The diagram is sometimes called the Fishbone diagram for its appearance. The diagram has been described and implemented by Kaoru Ishikawa. Ishikawa diagram is a cause-and-effect diagram, its purpose is to find the most probably cause of problem being solved. The quality of products and services cannot be improved unless we have found the real cause of the faults being generated. The Ishikawa diagram is a diagram of causes and their effects aimed at finding the most likely cause of the problem being solved.

0 kommentar(er)

0 kommentar(er)